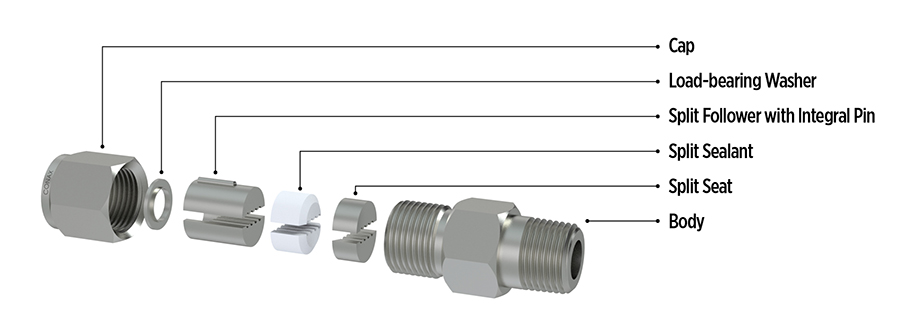

Conax SPGA/DSPGA Series – Multi-hole Split Compression Seal Fitting

Conax now offers split seal fittings with pressure ratings that are higher than typical ratings achieved with our legacy SPG and DSPG multi-hole split compression seal fittings

- Seals up to 12 Elements

- Multi-hole split seal fittings that carry both hydraulic and pneumatic catalog pressure ratings

- For liquid and gas

Our tightest split seal fitting ever

Conax Technologies now offers a split seal fitting with pressure ratings that are higher than typical ratings achieved with standard multi-hole split compression seal fittings. The new Conax SPGA is our first multi hole split seal fitting that carries both hydraulic and pneumatic catalog pressure ratings. So there’s no need to consult the factory when your application falls within the catalog ratings. Because the amount of pressure transmitted from the cap to the load-bearing washer, follower, sealant, and seat set is higher, the SPGA creates higher sealing pressures that result in a tighter seal on the fitting body and elements. Viton, Lava and Grafoil sealants are available.

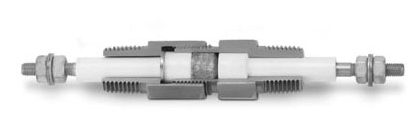

Conax split seals for multiple probe sealing

Conax Technologies offers various models of split seals designed to be used when the diameter of the probe tip is larger than the diameter of the elements at the location of the seal. Split fittings feature split sealants, followers, and seats, so the sealants can be easily changed without removing the elements from the system. Conax split seal fittings are used in down-hole oil and gas applications and for general industrial uses, including:

- Analyzer sampling probes with blow-out collars

- Gas-filled capillary bulb temperature sensors

- Cable assemblies with factory-installed connectors

- Easier assembly and disassembly of long cable/sheath probes