Magtrol Brakes and Clutches

Pure Hysteresis Brakes produce torque strictly through a magnetic air gap without the use of magnetic particles or friction components.

Like the Hysteresis Brake, the Magtrol Hysteresis Clutch develops torque strictly through a magnetic air-gap, ensuring an absolutely smooth transmission of torque from the drive unit to the driven element.

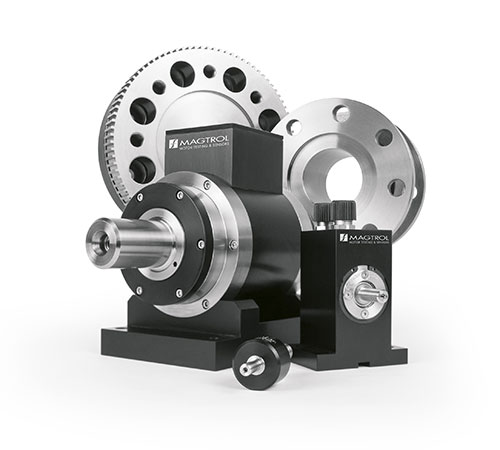

Brakes

Pure Hysteresis Brakes produce torque strictly through a magnetic air gap without the use of magnetic particles or friction components. This method of braking provides far superior operating characteristics (smoother torque, longer life, superior repeatability, high degree of controllability, and less maintenance and down time) which make them the preferred choice for precise tension control during the processing of nearly any material, web or strand.

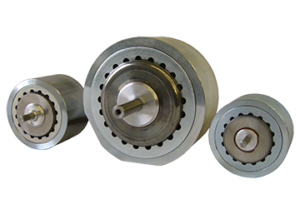

Clutches

Like the Hysteresis Brake, the Magtrol Hysteresis Clutch develops torque strictly through a magnetic air-gap, ensuring an absolutely smooth transmission of torque from the drive unit to the driven element. Designed to be powered without the use of brushes or slip rings, and being a pure hysteresis device, there is never any fear of contamination due to wear particles or leaky seals. This makes Magtrol Hysteresis Clutches and Brakes ideal for use in food processing and clean room environments.

Brake and Clutch Power Supplies

Magtrol offers four different power supplies for its Hysteresis Brakes: Model 5200, Model 5211, Model 5251-2 and BPM Series.

Brake and Clutch Selection

To properly size a brake or clutch, the operating parameters of MAXIMUM TORQUE (T), SLIP SPEED (rpm), and KINETIC POWER (watts) will have to be determined. Let Magtrol assist you in choosing the right brake or clutch for your needs.